The Importance of Material Handling Equipment for Your Business Success: Tips for Selecting the Right Tools

A. What Is Material Handling?

Material handling equipment refers to a wide range of tools and devices used in industrial and commercial settings to transport, store, and manage materials. These may include equipment such as conveyors, forklifts, cranes, hoists, and automated guided vehicles (AGVs).

Material handling equipment is critical for streamlining production processes, ensuring the safety of workers, and optimizing logistics and supply chain management. By providing efficient and effective methods for moving materials throughout a facility, businesses can improve productivity, reduce costs, and maintain a competitive edge in their industry.

Depending on the specific needs of a business, different types of material handling equipment may be required. Factors to consider when selecting material handling equipment include load capacity, size and shape of materials being handled, distance and height of transport, frequency of use, and safety considerations.

B. Importance of choosing the right tools for your business

If you work in a warehouse or similar facility, you are likely responsible for managing a large volume of products and materials. Ensuring that these items are not damaged during storage and are efficiently moved through production processes is essential to meet productivity targets and remain competitive in your industry. To achieve these goals, you need the right equipment and systems in place.

Material handling equipment (MHE) is a crucial component of any efficient warehouse operation. With the right MHE, you can handle materials with greater speed and accuracy, reducing the risk of damage to products and ensuring timely delivery to customers.

To ensure that your warehouse is properly equipped to handle the demands of your business, it’s important to understand the different categories of MHE available and their unique benefits. By investing in the right equipment and systems, you can streamline your operations, reduce costs, and stay ahead of the competition.

II. Types of Material Handling Equipment for Warehouses

Warehouse material handling equipment (MHE) is essential for the efficient movement and storage of materials within a warehouse or distribution center. Here are some common types of MHE used in warehouses:

Pallet Jacks: These are hand-operated devices used to lift and move pallets. Pallet jacks are typically used for short distances and can handle loads up to several thousand pounds.

pallet jacks are a very basic form of a forklift. They’re used to move materials around a warehouse and are often manually pushed, though there are powered options as well.

Forklifts: These are vehicles with lifting capabilities used to move heavy loads from one location to another. Forklifts come in various sizes and can handle loads ranging from a few hundred pounds to over 100,000 pounds.

Industrial trucks and forklifts cover a broad category of equipment. The one thing they have in common is that all of the pieces of equipment help with transportation. Industrial trucks and forklifts are available in a range of sizes. For example, you can find something small enough to be hand-operated, and you can also find equipment large enough to be driven.

Conveyor Systems: These are systems that move materials from one location to another, typically on a continuous loop. Conveyor systems can be used for horizontal or vertical transport of materials.

Automated Guided Vehicles (AGVs): These are self-driving vehicles used to move materials from one location to another without human intervention. AGVs are programmed to follow a set route and can be used to move materials throughout a facility.

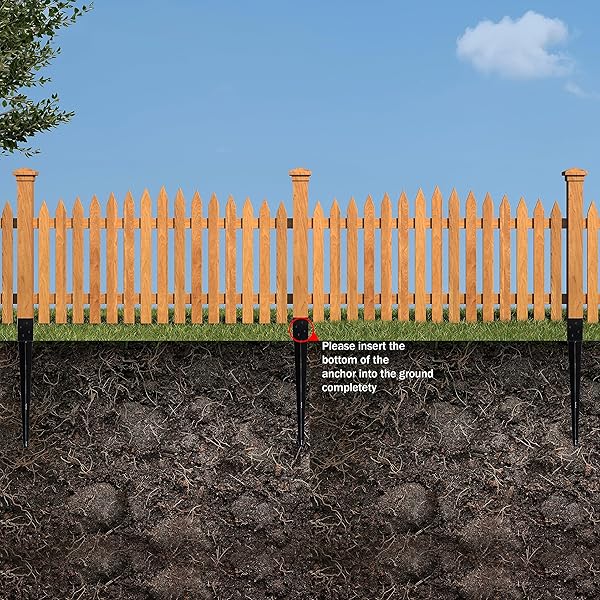

Shelving and Racking Systems: These are systems used to store materials and products in an organized and efficient manner. Shelving and racking systems can be designed to accommodate a wide range of materials and product sizes.

There are multiple types of racks used in facilities, including sliding racks, pallet racks, push-back racks, and drive-through or drive-in racks. These racks help to keep your material accessible and save floor space

A major benefit to this Storage and Handling Equipment is that they allow a company to be more efficient. A warehouse’s production system relies on its equipment and staff’s ability to access and transport materials quickly. You don’t want bottlenecks to form in the production process. Storage and handling equipment makes it easy for other pieces of equipment to pick up large quantities of materials and transport them from place to place.

Cranes: These are machines that use hoists and cables to lift and move heavy loads. Cranes are typically used to move materials vertically, such as loading or unloading cargo from ships or moving heavy equipment.

Lift Tables: These are devices used to raise and lower materials to a more comfortable working height. Lift tables can be used for loading and unloading trucks or for assembly work.

Order Pickers: These are vehicles used for picking items from high shelves or racks. They are designed to provide access to hard-to-reach items and can be used for order fulfillment.

Stretch Wrap Machines: These are machines used to wrap pallets with plastic film to secure and protect the load during transport.

By knowing more about these main categories, you’ll be more aware of the types of equipment that fit the needs of your company. The first step of building an effective material handling system is knowing your options.

What Are the Benefits of Material Handling Equipment?

Efficient material handling is vital for the success of any company. Poor storage and handling practices can result in product loss, damage to materials, and disruptions in the supply chain. To prevent these problems, investing in high-quality material handling equipment (MHE) that caters to the unique needs of your business and materials is crucial.

Here are some of the top advantages of implementing an effective material handling system in your company:

1-Increased Efficiency: MHE helps to streamline operations by moving materials quickly and efficiently, reducing the time it takes to complete tasks.

2-Improved Safety: MHE reduces the risk of workplace injuries by taking on the heavy lifting and transporting materials, which can prevent injuries caused by manual handling.

3-Cost Reduction: The use of MHE can lead to cost savings by reducing labor costs, minimizing product damage, and decreasing downtime.

4-Greater Flexibility: MHE can be customized to suit specific needs, allowing for greater flexibility in material handling and storage.

5-Improved Productivity: With the use of MHE, more materials can be moved in less time, allowing for increased productivity.

6-Increased Accuracy: MHE can improve accuracy in material handling, reducing the risk of errors in inventory and order fulfillment.

7-Better Space Utilization: MHE can help to optimize space utilization by maximizing vertical space in warehouses and using shelving and racking systems to organize materials.

In summary, investing in a good material handling system can provide distinct advantages to your company, including increased productivity, enhanced safety, improved quality control, reduced operating costs, and better customer service. By choosing the right MHE for your specific needs, you can ensure efficient material handling and optimize your supply chain for long-term success.

Contact Borhaf for Material Handling Solutions:

Upgrade your warehouse or facility with material handling solutions from Borhaf. As a warehouse material handling Metal Fabricator, we provide companies with material handling products and racking & shelving systems & steel stillages, Collapsible Wire Cage, Shelf Roll container,s and more.

We offer more than just material handling equipment for purchase. In addition to our products, we provide comprehensive services to help you develop new material handling facilities and get your operations up and running quickly. If you have any questions or concerns about managing materials in your warehouse or facility, please don’t hesitate to contact us. Our team of experts is always ready to assist you in finding the right solutions for your specific needs.